Neon has a long history, first appearing in exhibitions in France in 1900. At that time, neon was a gas lamp filled with thin neon gas or other electrically charged glasstubes or bulbs. It was a cold-cathode gas discharge lamp.

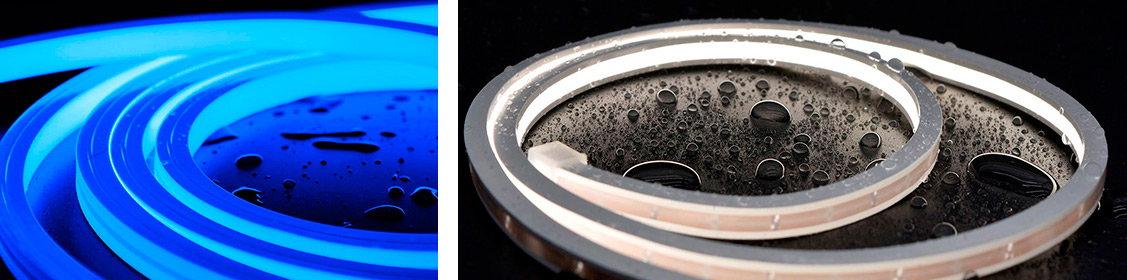

Neon lights through long-term development, to the flexible LED neon light band, since in 2015, began to appear on the market for silicone extrusion process of waterproof lights, neon lights with comprehensive upgrades, silicone environmental performance, strong flexibility, UV resistance, wider working temperature, yellowing resistance, acid and alkali resistant, light failure is small, the characteristics of good light transmittance, a new production process.

LED flexible silicone neon strip advantages are as follows:

1. Use environmentally friendly silica gel, non-toxic;

2. Extrusion silicone process, better waterproof performance, waterproof grade up to neon flex ip68;

3. Flexible silica gel, solved the original neon fragile shortcomings, in addition to a high flexibility, can be bent, twisted, pull, etc.

The neon strip itself can be placed for underwater work, but the two ends of the outlet position must meet the IP68 protection level can be placed for underwater work.

The bend Angle of the neon strip depends on the width of the strip. The narrower the width, the smaller the bend Angle. Paneralux offers a wide range of angles to choose from.

All products are guaranteed for three years with a life span of 30,000 + hours.

All products of the company have shear symbol, 24V products 50mm a shear, 12V products 25mm a shear.